It’s mid-October. For an e-commerce brand, this is the most critical time of the year. Your holiday inventory should be on the water, and you should be finalizing your Q1 2026 production plans. Then, the dreaded email from your supplier arrives: “We are writing to inform you of a small delay…”

This “small delay” is the start of a brand’s nightmare. In the world of global sourcing, production delays are not just an inconvenience; they are a direct and catastrophic threat to your revenue, cash flow, and brand reputation. While some delays are unavoidable, many are the direct result of unclear expectations and a lack of accountability.

A simple Purchase Order (PO) is not enough to protect you. The single most powerful tool you have for proactive supply chain risk management is a comprehensive manufacturing agreement. This guide will break down the essential supplier contract clauses you must include to prevent costly production delays and ensure on-time delivery.

The Foundation: Why a Handshake or PO Is Not Enough

Many new brands operate on a simple Purchase Order and a good relationship with their supplier. While a good relationship is crucial, a PO is merely a transactional document. It confirms what you’re buying, how much you’re paying, and a target ship date. It does not, however, clearly define the rules of engagement, the consequences of failure, or the detailed processes for ensuring quality.

A manufacturing agreement is your rulebook. It is a legally binding document that creates clarity and alignment for both you and your supplier before any problems arise. It transforms the relationship from a casual handshake into a professional partnership with clear, shared expectations.

The 5 Critical Clauses to Prevent Production Delays

To make your agreement a powerful tool, it must include specific, actionable clauses that directly address the most common causes of delays. Here are the five non-negotiable clauses.

1. The “Crystal Clear Lead Time” Clause

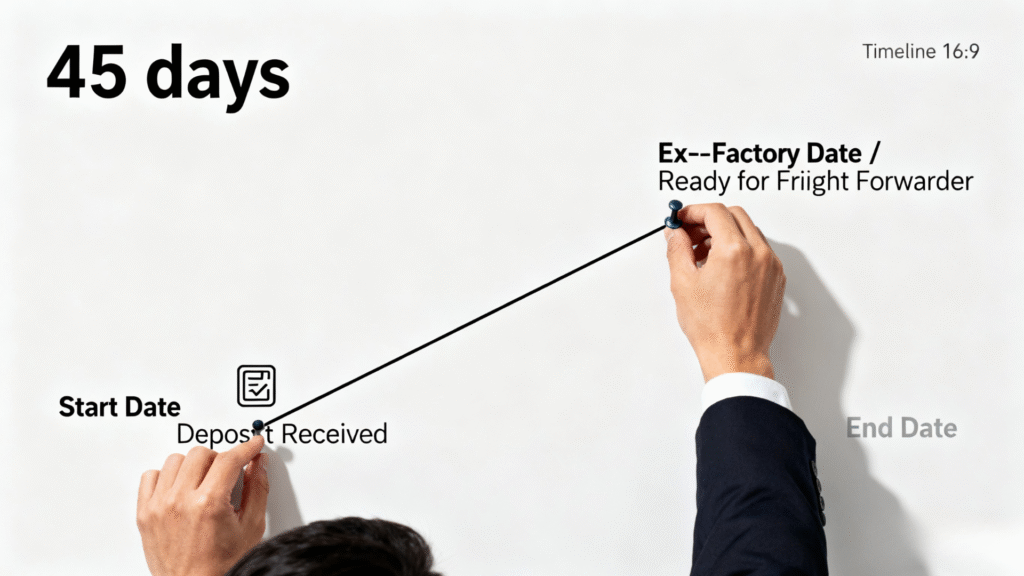

The most common source of disputes is a misunderstanding of when the clock starts and stops. Your agreement must define the production timeline with absolute precision.

- What it is: This clause defines the exact Lead Time for your production run, specified in calendar days, not business days.

- Why it’s critical: It eliminates all ambiguity.

- How to structure it:

- Define the Start Date: Clearly state that “Day 1” of the Lead Time begins on the next business day after the supplier confirms receipt of your deposit payment.

- Define the End Date: The Lead Time concludes on the “Ex-Factory Date.” This must be defined as the date that the goods have passed a final quality inspection and are made available for pickup by your designated Freight Forwarder. It is not the date they finish production.

- Example: “The Lead Time for this order is 45 calendar days, beginning on the first business day following the Seller’s confirmed receipt of the Buyer’s 30% deposit. The Lead Time concludes on the Ex-Factory Date, when the goods are fully packaged, have passed the final QC inspection, and are available for pickup.”

2. The “Late Delivery Penalty” Clause (Liquidated Damages)

This is the clause that gives your agreement teeth. It establishes a clear, pre-agreed financial consequence for missing the Ex-Factory Date. This is professionally known as a Liquidated Damages clause.

- What it is: A penalty, typically a percentage of the total order value, that the supplier agrees to deduct from the final balance payment for each day or week of delay.

- Why it’s critical: It creates a powerful financial incentive for the supplier to prioritize your production and meet their commitments.

- How to structure it:

- Be Fair and Specific: The penalty should be significant enough to be a deterrent, but not so punitive that a supplier refuses to sign. A common structure is 1% of the total order value per week of delay, often capped at 10-15% of the total value.

- Example: “In the event the Seller fails to meet the agreed-upon Ex-Factory Date, a late delivery penalty of 1% of the total Purchase Order value will be deducted from the final balance payment for each full week of delay. This penalty is capped at a maximum of 10% of the total Purchase Order value.”

3. The “Payment Tied to QC” Clause

Production delays are often caused by arguments over quality. A factory might finish production on time, but if the goods are defective, they are useless to you. This clause links your final payment directly to a successful quality inspection.

- What it is: This clause states that the 70% balance payment is only due after the goods have passed a final inspection by you or your designated third-party inspection company.

- Why it’s critical: It gives you maximum leverage. If there are quality issues, you have not yet paid the final balance, forcing the factory to take the rework seriously and quickly to get paid.

- How to structure it:

- Example: “The 70% balance payment is due within 3 business days following the Buyer’s receipt and written approval of a ‘PASS’ report from a third-party Quality Control inspection. The inspection will be arranged and paid for by the Buyer and will take place at the Seller’s facility prior to the Ex-Factory Date.”

4. The “No Unauthorized Subcontracting” Clause

A hidden cause of both delays and quality problems is when your trusted supplier secretly subcontracts part of your order to a cheaper, lower-quality factory without your knowledge.

- What it is: This clause explicitly forbids the supplier from subcontracting any part of your production to another facility without your prior written consent.

- Why it’s critical: It ensures that the factory you vetted and audited is the one actually making your product, maintaining the quality and production timeline you agreed upon.

- How to structure it:

- Example: “The Seller agrees that no part of the production or assembly of the goods specified in this agreement shall be subcontracted to any third-party facility without the express prior written approval of the Buyer.”

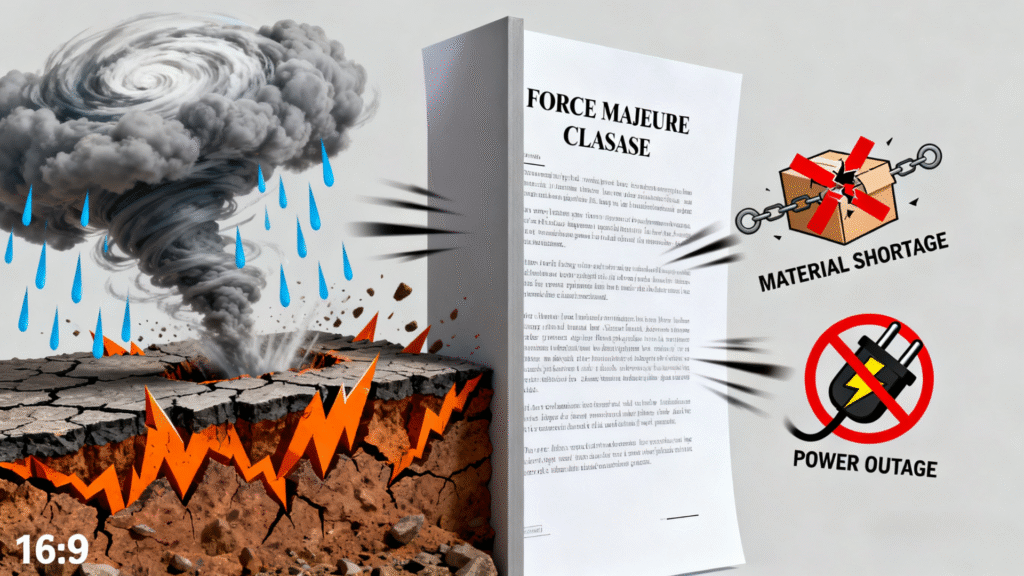

5. The “Force Majeure” Clause (Defined Narrowly)

This clause defines the “Acts of God” or other unforeseeable events that would legally excuse a supplier from a delay (e.g., major earthquakes, wars, floods).

- What it is: A standard legal clause outlining uncontrollable events.

- Why it’s critical: You must define this clause narrowly. A vague clause can be abused by suppliers to excuse themselves for preventable problems.

- How to structure it:

- Be Specific: Explicitly state what does not constitute Force Majeure. This should include common and foreseeable issues like raw material shortages, labor disputes, or regional power outages.

- Example: “For the purposes of this agreement, Force Majeure shall not include raw material or component shortages, labor shortages or disputes, or regularly scheduled or seasonal power outages in the Seller’s manufacturing region.”

Conclusion: Your Agreement is a Tool for Alignment

While it can feel confrontational to discuss penalties and legal clauses, a professional manufacturing agreement is the foundation of a healthy and successful partnership. Its primary purpose is not to punish, but to create absolute clarity and align incentives. It ensures that both you and your supplier are working from the same rulebook with the same definition of success: the on-time delivery of high-quality products.

In the fast-moving world of consumer electronics, proactive supply chain risk management is not a luxury; it’s a necessity. A strong agreement is your best insurance policy against the catastrophic cost of production delays.