It’s mid-November. Black Friday is days away. Your ads are running, your marketing emails are scheduled, and your customers are ready to buy. Then, the email arrives—the one that makes your stomach drop. Your primary supplier has defaulted. The goods are late, the quality is a disaster, or they simply can’t produce the volume.

This isn’t just a problem, it’s a five-alarm fire that threatens to burn down your entire holiday season. In this moment, your company’s survival depends on one thing: having a fast, decisive Emergency Sourcing Plan. This isn’t a typical procurement strategy; it’s a battlefield triage, and this is your action plan.

The New Mindset: Speed > Everything

First, you must accept the new reality. A standard sourcing process—with its long lead times, deep vetting, and focus on low cost—is a luxury you no longer have. Your normal priorities are irrelevant. The only goal of an Emergency Sourcing Plan is to get any acceptable, sellable product into your warehouse before the sales window closes for good. This means your new priorities, in order, are: 1. Speed, 2. Availability, and 3. Reliability. Cost is now the last and most flexible variable in your plan.

Step 1: Triage the Damage

Before you can activate your Emergency Sourcing Plan, you must know the exact size of the problem. You have 60 minutes to triage the damage with your current (failed) supplier. Ask them three non-negotiable questions:

- What is the exact, deliverable quantity? (Are you failing on 100% of the order, or 30%? Can you ship 5,000 units by air today?)

- What is the real root cause? (Is it a Quality Control (QC) failure, a raw material shortage, or a production line breakdown?)

- What is the guaranteed final ship date for the rest?

The answers to these questions will determine if your Emergency Sourcing Plan needs to replace the entire order or just a small, critical portion to get you through the peak sales weekend.

Step 2: Identify Your Emergency Suppliers

A good Emergency Sourcing Plan doesn’t mean finding a new factory from scratch—you don’t have time to conduct a factory audit. It means tapping into a pre-existing network of speed-based solutions. Your primary targets are:

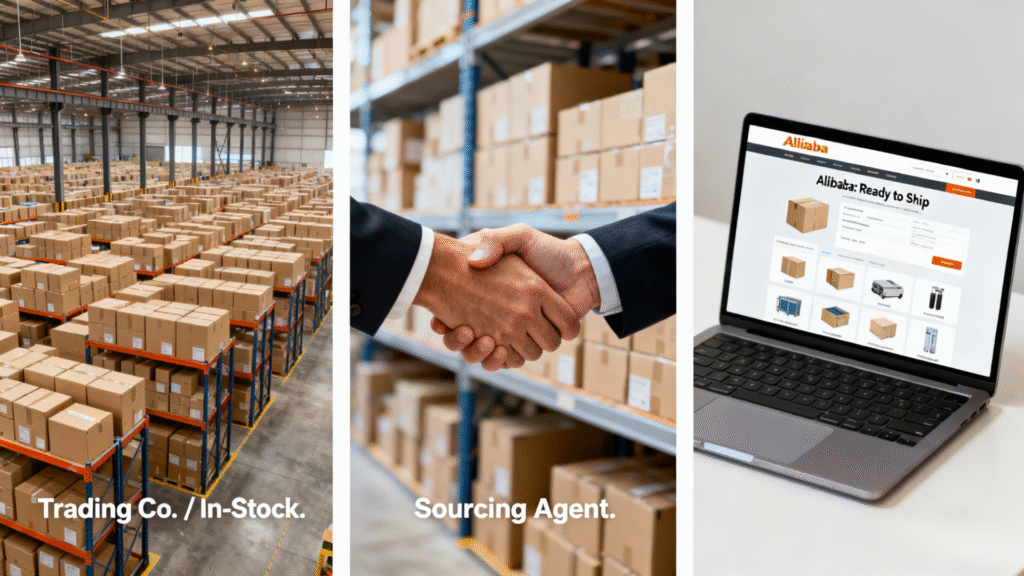

- Trading Companies & Wholesalers: These are your best bet. They don’t manufacture anything, but they hold existing stock of generic, unbranded products. You sacrifice all customization and margin, but you gain immediate availability.

- Your Sourcing Agent: If you have one, this is the moment they prove their worth. Their part of the Emergency Sourcing Plan is to call their “Plan B” factory—a trusted partner who can rush a small order as a personal favor.

- “Ready to Ship” Marketplaces: Using the “Ready to Ship” or “In-Stock” filter on Alibaba is a high-risk gamble. But as a last-ditch component of an Emergency Sourcing Plan, it’s a valid option to explore.

Step 3: Execute the Plan with Ruthless Efficiency

When you execute this Emergency Sourcing Plan, you must be decisive and willing to make compromises.

- Simplify Everything: Forget your custom-printed box, your logo, or your special Pantone color. Ask the new supplier for their generic, white-label product in any packaging they have on hand. Your goal is to remove every possible barrier to immediate shipment.

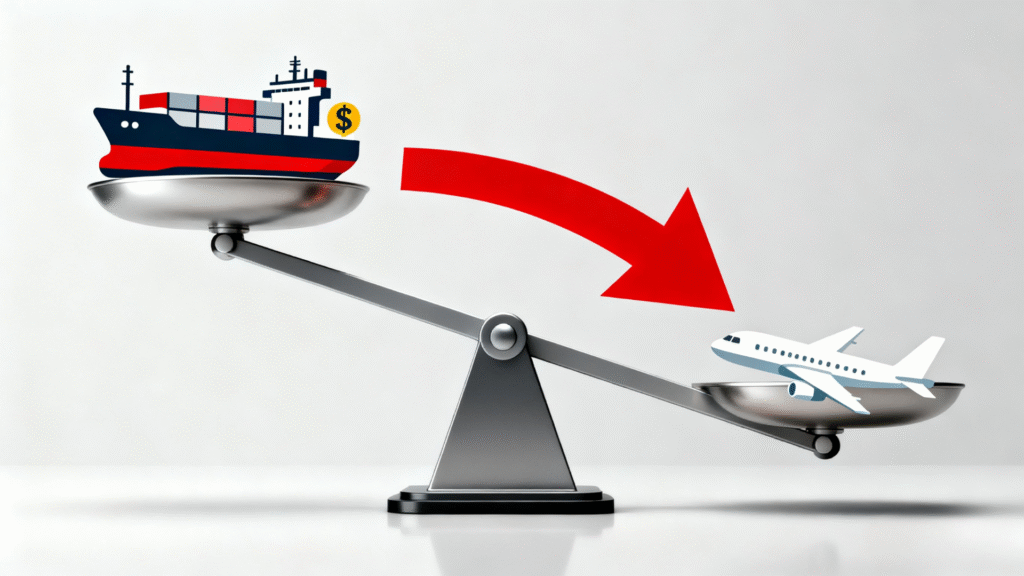

- Pay for Air Freight: This is a given and must be budgeted into your plan. Sea freight is not an option. Your profit on this emergency batch might be zero or even negative, but it might save your brand’s reputation and your retail partnerships.

- Pay Safely: Even in a panic, do not send a 100% T/T wire transfer to a new, unvetted supplier. Use a protected method like Alibaba Trade Assurance or an escrow service. A core part of any Emergency Sourcing Plan must be financial Risk Management.

Step 4: Turn Today’s Crisis into Tomorrow’s Strategy

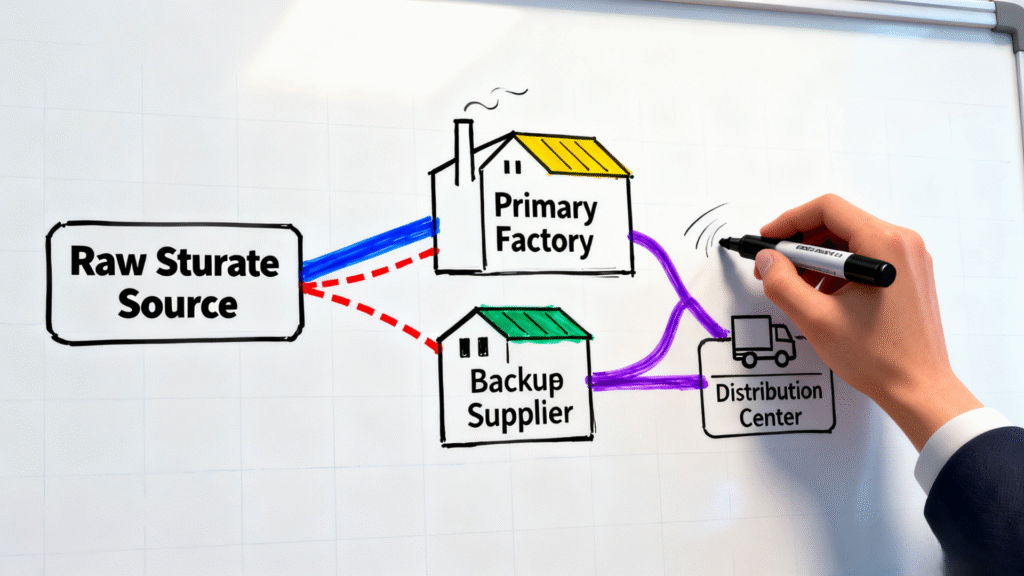

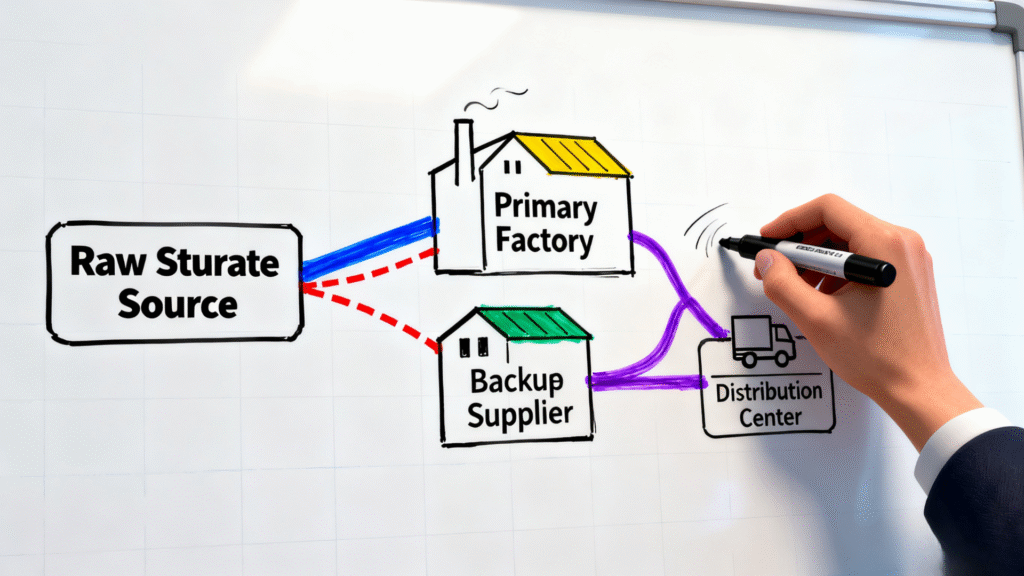

Surviving a peak-season supplier failure is a painful but powerful lesson. Once the dust settles in January, your most important task is to conduct a ruthless “post-mortem” analysis. Your goal is to ensure this never happens again. This crisis is the data you need to build a permanent, proactive Emergency Sourcing Plan for the future. This long-term strategy should include:

- A vetted, approved list of backup suppliers for your core products.

- A much stronger manufacturing agreement with your primary supplier, including a stiff late delivery penalty clause.

- A clear supply chain diversification strategy, so that one failure point can never again jeopardize your entire business.

body trimmer market trends

Want to capitalize on leading body trimmer market trends in 2026? Contact us for bespoke OEM design, compliance management, and logistics partnerships tailored to your business size and customer segment. Unlock smart technology, sustainable materials, and effective e-commerce solutions at every stage of your next product launch. Visit https://www.gzaimeitech.com/ to connect with innovative manufacturers and stay ahead in the rapidly evolving body trimmer market.