It’s early September. While your marketing team is focused on the upcoming holiday season, seasoned importers and procurement managers have their sights set on a period in Q1 2026 that can make or break their entire year: Chinese New Year. For unprepared businesses, the massive CNY factory shutdown is the single largest Supply Chain Disruption of the year, leading to catastrophic production delays, shipping logjams, and critical inventory stockouts that can last for months.

But it doesn’t have to be a crisis. With foresight and a clear strategy, you can navigate this period smoothly. This guide will answer the top five questions that every procurement manager asks when preparing their Chinese New Year supply chain strategy, providing a clear roadmap to protect your business and stay ahead of the competition.

1. When do factories actually close for Chinese New Year 2026, and for how long?

This is the most critical and most misunderstood question. The official public holiday is only about a week long, but the real disruption to your manufacturing in China lasts for well over a month. You must plan for the full shutdown period, not just the official holiday dates.

Here is a more realistic timeline of what to expect:

- 2-3 Weeks Before CNY (Early-to-Mid January 2026): Production begins to slow down significantly. Many factory workers are migrants from other provinces and will leave early to begin the long journey home to their families.

- 1 Week Before CNY (Late January 2026): Most factories are completely shut down. This marks the beginning of the official dead period where no production or domestic logistics will occur.

- 1-2 Weeks After CNY (Early-to-Mid February 2026): The factory officially reopens, but it is running on a skeleton crew. Workers slowly trickle back over a period of weeks. It is very common for some workers not to return at all, leading to high staff turnover.

- 3-4 Weeks After CNY (Late February/Early March 2026): Production slowly ramps back up to normal levels. Be aware that quality issues are most common during this period due to new, untrained staff on the assembly lines.

The B2B Insight: Your supply chain planning must account for a total disruption of at least 4 to 6 weeks. Any Production Schedule that doesn’t include this buffer is destined for failure.

2. How does the CNY shutdown affect the entire supply chain, not just production?

The “CNY effect” is a massive domino effect. The factory closure is just one piece of the puzzle. The entire logistics infrastructure of the country grinds to a halt, and the ripple effects are felt globally.

- Before the Shutdown (December & January): This is the “Great Rush.” Every brand is desperately trying to get their products finished and shipped before the holiday begins. This causes:

- Overloaded Factories: Quality control often suffers as factories rush to meet deadlines.

- Port Congestion: Ports become incredibly crowded with trucks trying to deliver containers.

- Lack of Shipping Space: It becomes very difficult and expensive to book a container on a vessel. Shipping prices can skyrocket.

- During the Shutdown (Late Jan to Mid-Feb): Everything stops. No products are being made, no trucks are running to the ports, and port operations are minimal.

- After the Shutdown (Late Feb & March): This is the “Second Rush.” As factories slowly come back online, they all try to ship out their backlogged orders at the same time, leading to another period of intense port congestion and high shipping rates.

The B2B Insight: You cannot separate your production planning from your logistics planning. You must work closely with your Freight Forwarder and plan your shipping from China before CNY weeks, if not months, in advance to secure vessel space at a reasonable price.

3. What are the most critical production deadlines before Chinese New Year?

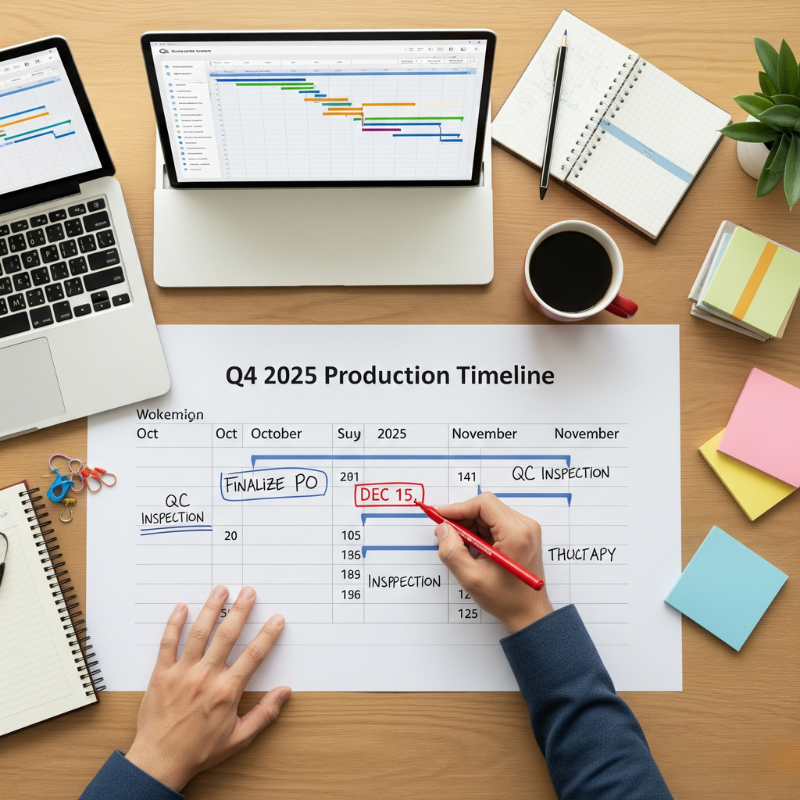

To navigate CNY successfully, you must work backwards from the shutdown date. A proactive timeline is the most effective tool for Risk Mitigation. Here is a sample timeline for any brand planning for the Q1 2026 shutdown.

| Deadline (Working Backwards from Shutdown) | Action Item | B2B Rationale |

| 4-5 Weeks Before Shutdown | All goods should be finished, inspected, and delivered to the port. | This is the absolute last call to get your shipment out before the holiday chaos begins and prices soar. |

| 7-8 Weeks Before Shutdown | Mass production should be completed. | This leaves a critical 2-3 week buffer for final Quality Control inspection and allows for any necessary rework. |

| 10-12 Weeks Before Shutdown | Your final Purchase Order (PO) for pre-CNY stock should be placed with your supplier. | This gives the factory enough time to source all their raw materials before their own suppliers start slowing down. |

| 14+ Weeks Before Shutdown (i.e., September/October 2025) | Finalize your Demand Forecasting and Inventory Management strategy for all of Q1 and Q2 2026. | You must make the strategic decision now about how much inventory you need to survive the entire disruption period. |

4. What is the best Inventory Management strategy to survive the shutdown?

Your goal is to have enough stock to cover sales during the shutdown and the slow production ramp-up period afterwards, without tying up all your cash in excess inventory.

- Forecast for 3-4 Months: Use your historical sales data to create a realistic Demand Forecasting model for February, March, and April. Don’t forget to account for any planned marketing promotions.

- Increase Your Safety Stock: Based on your forecast, calculate how much inventory you need to cover this period. Then, add an additional “safety stock” buffer of 20-30% to account for potential sales spikes or post-CNY production delays.

- Communicate with Your Supplier: Be transparent about your Q1 and Q2 inventory needs. A good long-term supplier will appreciate this foresight and work with you to create a production plan that ensures you are well-stocked.

5. How can we best communicate with our suppliers to ensure a smooth process?

Clear, proactive, and respectful communication is the single most important factor in a successful pre-CNY production run.

- Confirm Schedules in Advance (October): Ask your primary contact for the factory‘s official holiday schedule. Key questions to ask: “What is the last day you will accept raw materials?” “What is the final day for finished goods to leave the factory?” “When do you expect to be back at 80% production capacity in March?”

- Lock in Your Orders: Provide your final, detailed POs as early as possible. Avoid making any last-minute changes to the product design or packaging in Q4, as this can cause major delays.

- Build Goodwill: Chinese New Year is the most important cultural holiday in China. Send a simple holiday greeting to your key contacts. A small gesture that shows you respect their culture goes a long way in strengthening your Supplier Relationship Management (SRM).

Conclusion: Plan Now, Relax Later – Chinese New Year supply chain

Navigating the Chinese New Year supply chain disruption is a rite of passage for every importer. It is the ultimate test of a brand’s planning, forecasting, and communication skills. By treating the CNY shutdown not as an unexpected crisis, but as a predictable event to be managed, you can protect your business from stockouts, keep your customers happy, and start the new year from a position of strength and stability. The planning you do in the next three months will determine your success in the first quarter of 2026.