As we navigate the economic landscape of late 2025, a powerful consumer sentiment is reshaping the electronics industry. Faced with inflation and a desire for more conscious consumption, a growing number of US consumers are rejecting the “throwaway” culture of the past. They are embracing a “Buy It for Life” (BIFL) mentality, creating a powerful new demand for durable product design that prioritizes longevity and quality over the lowest possible price. -Body Trimmers Towards

This shift presents a critical strategic question for every brand in the personal care space. For years, plastic has been the undisputed king of body trimmer construction. But will this BIFL trend finally force a significant shift for body trimmers towards more premium and robust materials like aluminum and steel? This article will analyze the forces behind this trend, weigh the pros and cons of plastic versus metal, and explore what a move towards durable product design means for your brand’s strategy in 2026.

The “Why”: Drivers of the “Buy It for Life” Trend

This isn’t a fleeting fad; it’s a deep-seated change in consumer psychology, driven by three key factors.

- Economic Prudence: Consumers are tired of repurchasing the same item every two years. They are increasingly willing to pay more upfront for a product they believe will last, viewing it as a better long-term investment. This is a direct rejection of Planned Obsolescence.

- Sustainability Backlash: The environmental cost of disposable electronics is a major concern. A durable product that lasts for years has a significantly smaller carbon footprint than one that ends up in a landfill. This aligns with the principles of the Right to Repair movement and the broader push for a circular economy.

- The Quest for Perceived Value: In a world of minimalist aesthetics, the material is the message. The cool, solid feel of metal in the hand communicates a sense of quality and permanence that plastic often cannot match. This tactile experience is a key component of a premium brand’s Value Proposition.

The Case for Plastic Housings (The Status Quo)

Before we declare metal the future, it’s crucial to understand why plastic has dominated for so long. It remains a formidable choice for several valid reasons.

- Cost-Effectiveness: Plastic is significantly cheaper to source and manufacture than metal, leading to a lower Bill of Materials (BOM) and a more accessible retail price.

- Design Freedom: Injection molding allows for complex, highly ergonomic shapes that are comfortable to hold and use. Creating these same intricate curves in metal is far more difficult and expensive.

- Lightweight & Portability: Plastic is inherently lighter, making the device easier to handle and more convenient for travel.

- Inherent Properties: Plastic is a natural insulator and is easily made waterproof, both critical features for a wet and dry groomer.

The Case for Metal Housings (The Future Trend)

A shift for body trimmers towards metal housings is a direct response to the BIFL trend. Metal offers a powerful combination of tangible and intangible benefits that align perfectly with this new consumer mindset.

| Feature | The Benefit of Metal Housings | B2B Strategic Implication |

| Unmatched Durability | Anodized aluminum or stainless steel housings are far more resistant to drops, scratches, and long-term wear, directly delivering on the promise of product longevity. | Enables brands to offer longer warranties (e.g., 3-5 years), a powerful marketing tool. |

| Premium Perceived Value | The cool touch, satisfying heft, and solid feel of metal instantly communicate quality. This is a core part of the Quiet Luxury and premium materials trend. | Justifies a higher retail price point and positions the brand in a more premium segment of the market. |

| Enhanced Heat Dissipation | Metal is a better thermal conductor, which can help dissipate heat from high-performance motors, improving performance and lifespan. | A key selling point for “pro-grade” or high-performance models. |

| Ultimate Recyclability | Metals like aluminum are infinitely recyclable with very high efficiency, offering a powerful sustainability story beyond just using recycled plastics. | Aligns with corporate ESG (Environmental, Social, Governance) goals and appeals to eco-conscious consumers. |

The B2B Reality: What a Shift to Metal Actually Means

Embracing durable product design with metal housings is a significant strategic decision with major implications for your procurement and manufacturing process.

- A Higher BOM Cost: This is the most obvious factor. A CNC-machined aluminum housing is significantly more expensive than an injection-molded plastic one. This increased cost must be factored into your cost forecasting and pricing strategy.

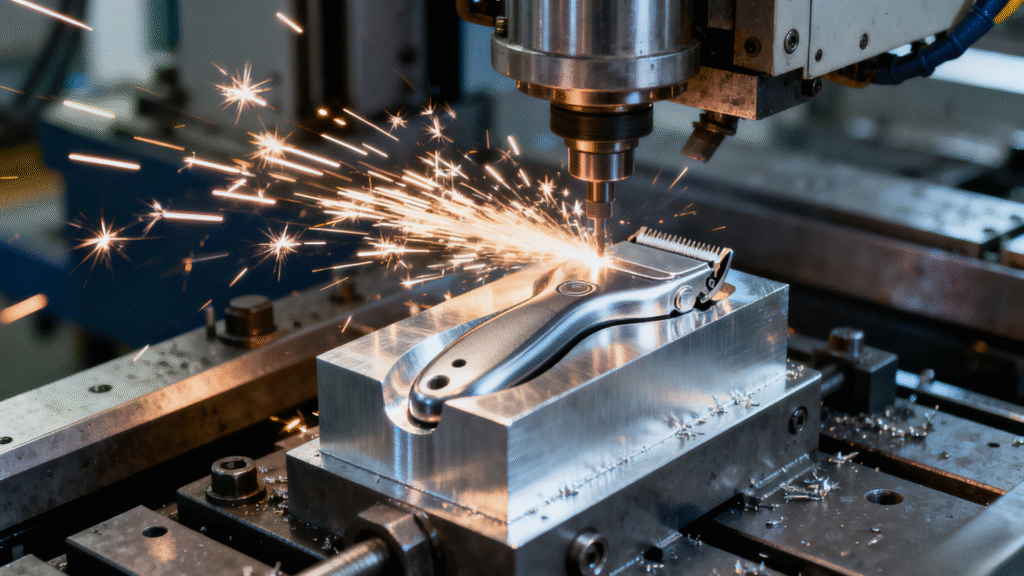

- New Manufacturing Expertise: The required manufacturing processes are completely different. You need a supplier with proven expertise in CNC machining, anodizing (for aluminum), or metal stamping, as well as the precision assembly required for these parts.

- Design and Engineering Challenges: Designing for metal is different. Engineers must focus on

Value Engineeringto optimize the design for manufacturing efficiency, manage the increased weight to ensure good ergonomics, and engineer solutions for things like radio transparency (for Bluetooth) that plastic handles naturally. - A New CMF Strategy: Your Color, Material, and Finish (

CMF) strategy becomes paramount. The choice of finish (e.g., bead-blasted vs. brushed aluminum) and the anodizing color will define the product’s entire aesthetic.

Conclusion: Will Metal Be the New Standard?

So, will the “Buy It for Life” trend create a complete shift for body trimmers towards metal housings in 2026?

The answer is likely a strategic split. We will not see a wholesale abandonment of plastic; it remains the best choice for entry-level and many mid-range products due to its cost and design flexibility.

However, for the premium mid-market and high-end segments, yes, metal is the future. A beautifully crafted aluminum or steel body will become a key signifier of a premium, durable, and sustainable product. It will be the most tangible way for a brand to differentiate itself and cater to the growing segment of consumers who are tired of disposable electronics.

For brands, the decision to adopt metal is a Brand Positioning choice. For manufacturers, developing expertise in both high-quality plastic and precision metal manufacturing is no longer an option—it’s a necessity to serve the full spectrum of the evolving market.