For the past two decades, the design philosophy for many small electronics, including body trimmers, has been dominated by the concept of “sealed-box” design. Devices are ultrasonically welded shut, batteries are glued in, and proprietary screws are used to discourage any attempt at home repair. The unwritten rule was simple: if it breaks, you buy a new one.

That era is officially coming to an end.

A powerful consumer and legislative movement known as Right to Repair is gaining irreversible momentum. With landmark legislation already passed in the EU and key US states like New York and California, brands are being legally mandated to make their products more repairable.

For brands currently planning their 2026 product roadmap, this is not a minor compliance issue; it is a fundamental engineering and design revolution. This trend will change how your body trimmer is built, what it’s made of, and how you manage its entire lifecycle. This article explores the specific, tangible design changes you need to start engineering today.

What Is the Right to Repair Movement, and Why Does It Matter for Grooming?

At its core, the Right to Repair movement is a simple idea: consumers should have the right to fix the products they own. This is being enforced through laws that require manufacturers to:

- Make spare parts available (to both consumers and independent repair shops).

- Design products that can be disassembled using common tools.

- Publish diagnostic and repair manuals.

For a body trimmer, this presents an immediate and profound engineering challenge. How do you design a device that is both easily disassembled by a user and maintains the IPX7 waterproof rating that has become a market standard?

The B2B Insight: This is no longer a question of “if,” but “how.” Brands that resist this trend will face legal penalties and significant consumer backlash. Brands that embrace it first will gain a powerful marketing advantage, positioning themselves as leaders in transparency, sustainability, and durable product design.

The Most Obvious Change: The End of the Glued-In Battery

The single biggest target of the Right to Repair movement is the non-replaceable battery. This is the component that defines a product’s lifespan, and its failure is the #1 reason a perfectly good trimmer gets thrown away.

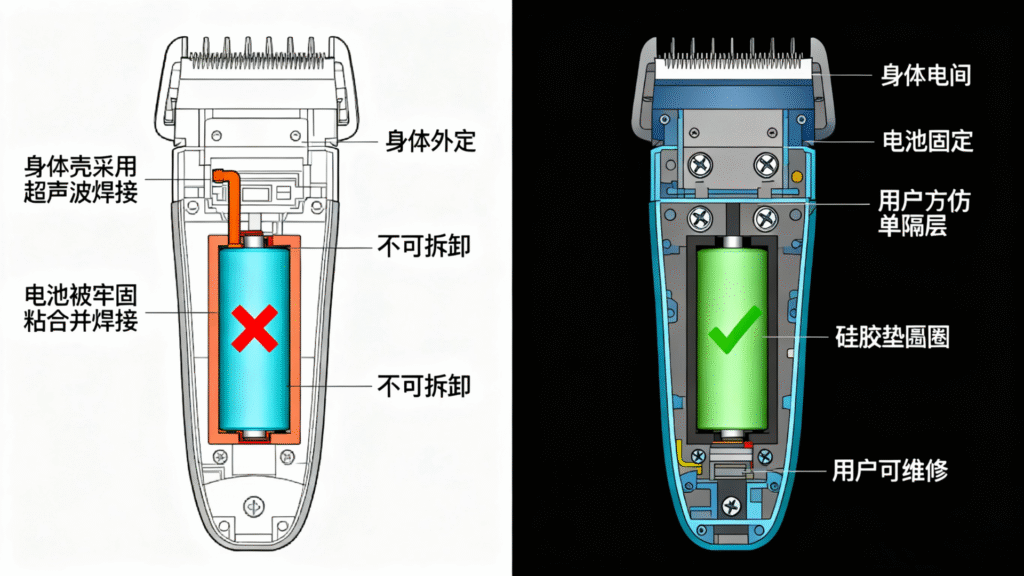

- The Old (Current) Design: To achieve a sleek look and a simple waterproof seal, most body trimmers have their lithium-ion batteries soldered directly to the PCBA and sealed inside a housing that is ultrasonically welded shut. It is impossible to replace without destroying the device.

- The 2026 (R2R) Design: Future designs will be legally required to have user-replaceable batteries. This forces a complete redesign of the product’s core architecture. Designers will have to engineer a dedicated battery compartment, accessible to the user with standard tools (like a small Phillips screwdriver).

- The Core Engineering Challenge: The new, critical design challenge will be waterproofing this user-accessible compartment. This will require precision-molded silicone gaskets and robust, screw-down enclosures—an engineering task that is complex but entirely possible, drawing inspiration from the R&D in medical devices and rugged electronics.

The Rise of Modular, “Snap-Fit” Components

This trend goes far beyond just the battery. The Right to Repair philosophy favors a modular product design where key components are treated as replaceable “modules.”

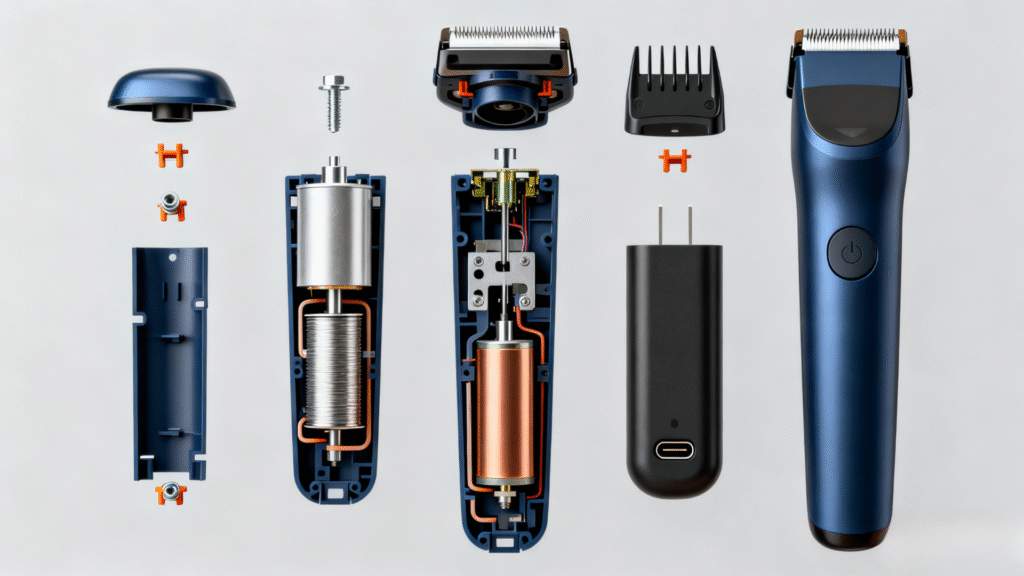

- Old Design: A single, complex internal chassis holds the motor, PCBA, and charging port, all interconnected. If the motor fails, the entire device is waste.

- New Design: A modular design separates the core components.

- The Motor Module: The motor and blade drive-shaft could be a single, replaceable cassette that snaps or screws into place.

- The Charging Port: This is another common point of failure (due to water or mechanical stress). A repairable design would feature a small, modular charging port that can be easily unplugged and replaced, rather than being soldered permanently to the main logic board.

This move to modularity will be a key part of your 2026 product roadmap planning.

A New Supply Chain: The “Spare Parts” Business Model

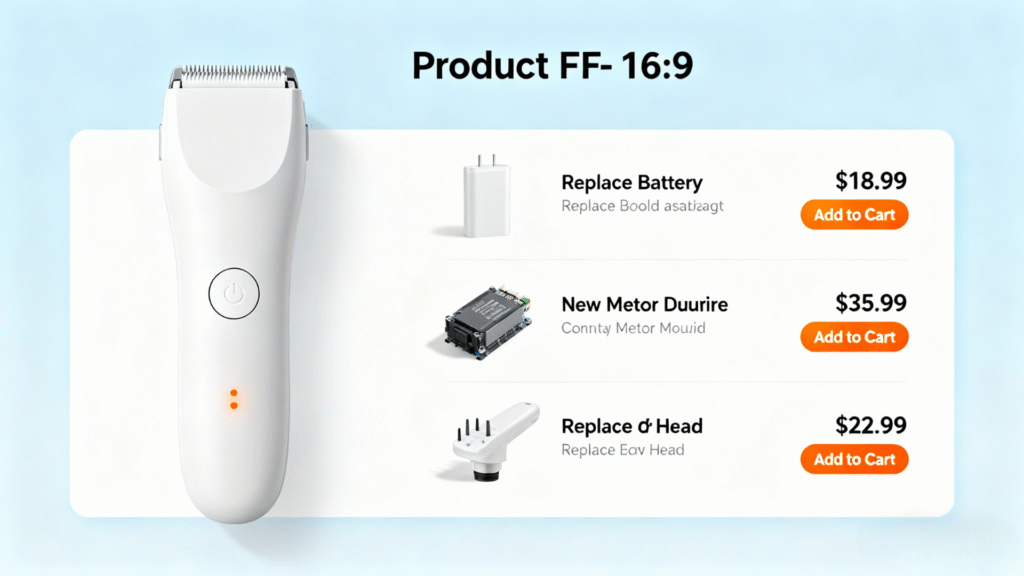

This design revolution forces a complete rethink of your post-sale business model. This isn’t just an engineering trend; it’s a business model transformation.

| Old Model: “Disposable” | New Model: “Repairable” (GaaS-adjacent) |

| Revenue is 100% from new device sales. | Revenue is diversified between new device sales and high-margin spare parts sales. |

| Customer relationship ends after the 1-year warranty expires. | Customer relationship is continuous, built through a spare parts and service ecosystem. |

| Brand focus is on lowering manufacturing cost. | Brand focus is on product longevity and customer lifetime value (LTV). |

The B2B Insight: Brands must partner with manufacturers who can not only build the primary device but also reliably produce and package a separate line of spare parts (batteries, motor modules, blade heads) for years to come. This creates a new, complex challenge for inventory management but also a valuable, recurring revenue stream.

Conclusion: From “Sealed Box” to “Serviceable System”

The Right to Repair trend is fundamentally shifting our industry’s definition of a “quality” product. In the past, quality meant a device that wouldn’t break for two years. In 2026, quality will mean a device that can be easily fixed when it eventually does.

This is a profound challenge for product design and manufacturing. It demands a shift away from “sealed-box” thinking and towards a new philosophy of modular, accessible, and durable design. The engineering hurdles, particularly around waterproofing, are significant.

But for the brands and manufacturers who solve them first, the reward is immense. You won’t just be compliant with the law; you’ll be offering a product that aligns with modern consumer values, builds long-term trust, and creates a sustainable business model for the future.

body trimmer market trends

Want to capitalize on leading body trimmer market trends in 2026? Contact us for bespoke OEM design, compliance management, and logistics partnerships tailored to your business size and customer segment. Unlock smart technology, sustainable materials, and effective e-commerce solutions at every stage of your next product launch. Visit https://www.gzaimeitech.com/ to connect with innovative manufacturers and stay ahead in the rapidly evolving body trimmer market.