It’s late September. While your marketing team is putting the final touches on your Black Friday campaigns, a critical question is keeping every procurement manager and brand owner awake at night: Have we missed the final sea freight deadlines? If your holiday stock is still sitting in a factory in Asia and not on a boat, we have to be direct: you are bordering on a crisis.

The average ocean freight transit times you see online don’t account for the brutal reality of Q4 logistics. This is the Peak Season, a period defined by skyrocketing shipping rates, intense port congestion, and a cascade of unforeseen delays that can derail your entire holiday sales strategy.

This isn’t a theoretical guide. This is an emergency briefing to answer the most urgent question in global trade right now: What are the final sea freight deadlines for your Holiday 2025 inventory, and what can you do if you’re already behind schedule?

1. Understanding the Q4 Shipping Gauntlet

To understand the deadlines, you must first understand why this period is so notoriously difficult. Standard Lead Time calculations do not apply in Q4.

- The Pre-Holiday Rush: Virtually every major US retailer and e-commerce brand is trying to ship their inventory from Asia at the exact same time. This creates unprecedented demand for limited container space on vessels.

- Crippling Port Congestion: This massive influx of ships overwhelms destination ports like Los Angeles and Long Beach. A container can arrive off the coast of California and then sit on a ship for one, two, or even three weeks before it can be unloaded.

- Domestic Delays: Once unloaded, the containers face further delays due to shortages of truck chassis and warehouse space.

- The Pre-CNY Overlap: Adding to the chaos, factories are also beginning to rush production for orders that need to ship out before the Chinese New Year shutdown in early 2026. This puts even more strain on the system.

This combination of factors creates the “Q4 Gauntlet.” It’s a predictable annual crisis, and the key to survival is respecting the deadlines.

2. The Critical Deadlines You Need to Know (Right Now)

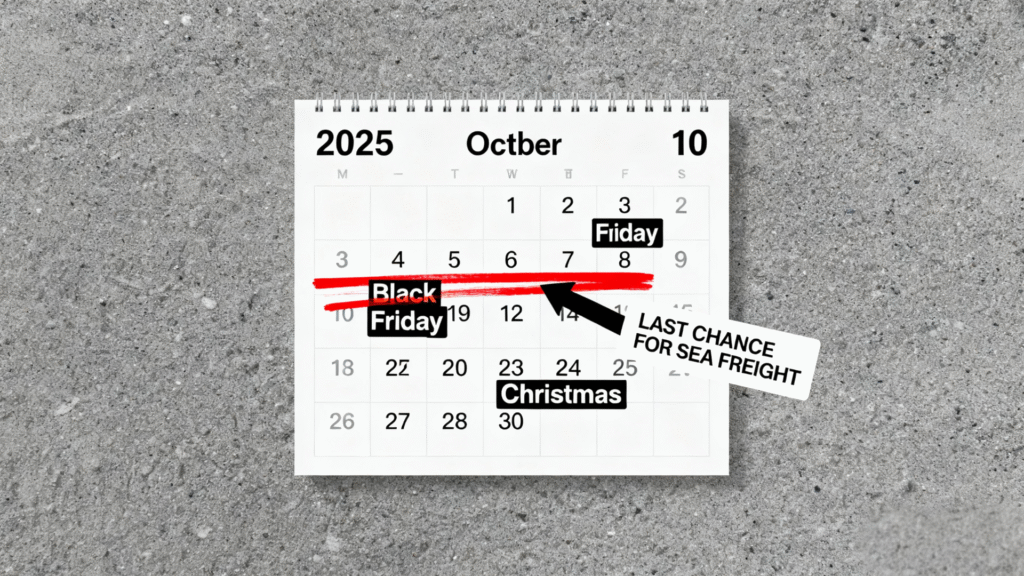

Let’s be direct. To calculate your deadlines, you must work backward from the date you need the inventory in your US warehouse. A safe estimate for total transit in Q4 is 50-60 days from the day the vessel sails, which includes ocean transit, port delays, and domestic trucking.

Based on this, here are the realistic deadlines for the 2025 holiday season.

| Holiday / Event | To be on US Shelves/Warehouse by… | Your “Goods Must Be on the Water” Deadline | Critical Note for September 28th |

| Thanksgiving / Black Friday | November 15, 2025 | EARLY OCTOBER (OR EARLIER) | CRITICAL RISK. You have likely missed the standard sea freight window. Emergency action is required. |

| Christmas | December 5, 2025 | MID-OCTOBER (IN 2-3 WEEKS) | HIGH RISK. This is your absolute final window for standard sea freight. You must confirm a booking with your freight forwarder this week. |

| General Q4 Stock | Mid-December 2025 | LATE OCTOBER | Moderate risk. Unforeseen delays could easily push your final delivery into January 2026. |

3. “I’m Behind Schedule!” – Your Emergency Action Plan

If you’re reading this in late September and your goods are still in the factory, deep breaths. You have options, but you need to act immediately.

- Contact Your Freight Forwarder NOW: Your logistics partner has the most up-to-date information on vessel availability, port conditions, and premium shipping options. Be transparent about your deadlines and ask for their most realistic ETA.

- Explore Premium / Expedited Sea Freight: Some ocean carriers offer faster (and more expensive) services that can sometimes shave 7-10 days off the transit time. Ask your forwarder if this is a viable option for your route.

- Consider a Split Shipment: This is a common Risk Mitigation strategy. Ship a small, critical portion of your inventory (e.g., 10-20%) via air freight to ensure you have some stock for your most important Black Friday sales. Send the rest of the inventory via standard sea freight.

- Analyze the Air Freight vs Sea Freight Cost: This is the painful but necessary calculation. Air freight can be 5-10x more expensive than sea freight. However, you must calculate the cost of lost sales if you have zero inventory during the biggest shopping weekend of the year. Often, the high cost of air freight is a better business decision than the catastrophic cost of a total stockout.

4. A Look Ahead: How to Never Miss the Holiday Shipping Deadlines Again

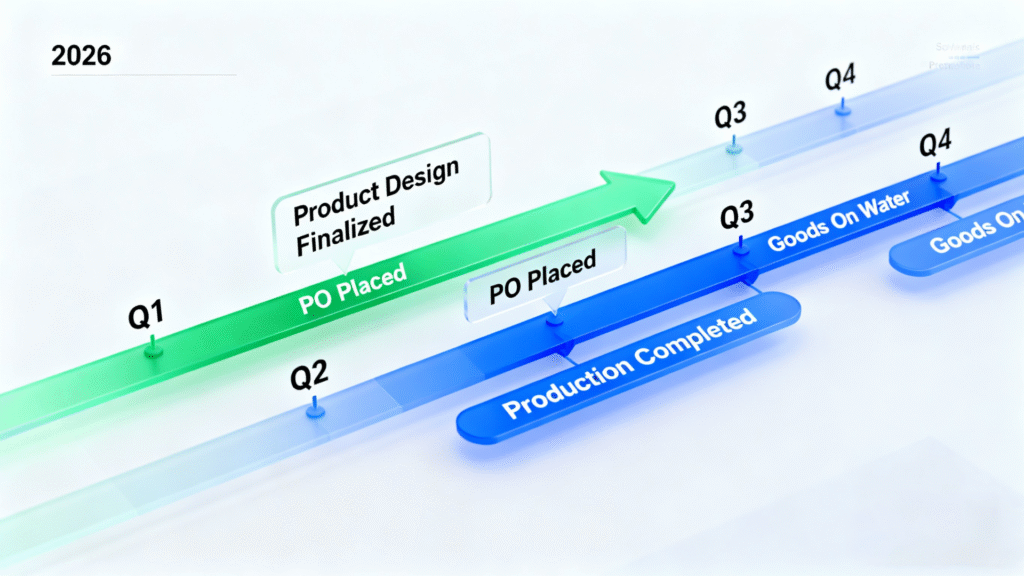

Use the stress of this year’s shipping crunch as the motivation to perfect your planning for 2026. Successful Supply Chain Management for the holiday season is not a Q3 activity; it’s a Q2 activity.

A simple planning calendar for next year:

- April – June 2026: Finalize your holiday product designs and place your POs with suppliers.

- July – August 2026: Your mass production should be underway. Start gathering initial shipping quotes from your freight forwarder.

- Early September 2026: Production should be finished and undergoing final QC inspections.

- Mid-to-Late September 2026: Your goods should be loaded onto a vessel and sailing across the ocean.

Conclusion: Act Now, Plan for Later

If your Holiday 2025 inventory is not already on a ship or booked to be on one in the next two weeks, you are in a high-risk situation that requires immediate and decisive action. Contact your logistics partners, be prepared to spend more on faster shipping options, and make a clear-eyed calculation about the true cost of a stockout.

Most importantly, let this year be a lesson. A brand’s success in Q4 is determined by the discipline and foresight of its Logistics Planning in Q2 and Q3. Use this experience to build a more resilient and proactive holiday inventory plan for 2026, so that next September, you can focus on marketing, not last-minute shipping crises.